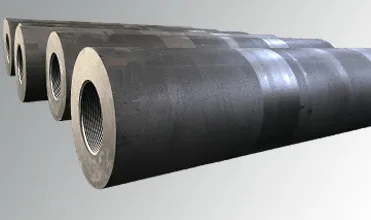

Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called “mini-mills”. They are also used in the refining of steel as well as in the non ferrous industries, where smelting processes are in use.

Graphite Electrode

ite Electrode for Scrap Steel Meltingngda graphite electrode

As we know, there are two ways to make iron. The blast furnace method and the electric arc furnace method. Graphite electrodes are widely used in electric arc furnace (EAF) and ladle furnace (LF) for steel production. It is the graphite electrodes inside the furnace that actually melt the iron. Graphite has high thermal conductivity and is very resistant to heat and impact. It also has low electrical resistance, which means it can conduct the large electrical currents needed to melt iron.

Graphite Electrodes Grades:

• Ultra-high power (UHP) electrode

• High power (HP) electroe

• Regular power (RP) electrode

Graphite Electrode For DC Furnaces(direct current furnaces)/ Size: 22-32 inches

DC electric arc furnaces requires 1 column of graphite electrodes and high maximum current density.

The diameter of these electrodes is getting bigger: the current maximum diameter is 32 inches (800 mm).

Graphite Electrodes For AC EAF Furnaces (alternating current furnaces) / Size: 16-28 inches.

Alternating current EAF requires 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

For LF Furnaces (refining furnaces) / Size: 10-18 inches

These electrodes are for refining materials like molten steel. LF Furnaces have a smaller capacity than DC

russia graphite electrode

Graphite Electrode Specifications:

| Items | UHP |

HP |

RP |

|||

| Φ300-φ500 |

Φ550-φ800 |

Φ200-φ800 |

Φ200-φ800 |

|||

|

Resistivity (uΩ m max) |

Electrode |

4.8-5.8 |

4.6-5.8 |

5.8-6.6 |

7.0-10.0 |

|

|

Nipple |

3.5-4.0 |

3.5-4.0 |

3.5-4.0 |

4.0-4.5 |

||

|

Modulus of rupture(Mpa) |

Electrode |

10.0-14.0 |

10.0-14.0 |

10.0-13.0 |

8.0-10.0 |

|

|

Nipple |

20.0-24.0 |

22.0-26.0 |

20.0-23.0 |

19.0-22.0 |

||

|

Young's modulus(Gpa) |

Electrode |

9.0-13.0 |

10.0-14.0 |

8.0-12.0 |

7.0-9.3 |

|

|

Nipple |

15.0-18.0 |

16.0-19.0 |

14.0-16.0 |

12.0-14.0 |

||

|

Bulk Density (g/cm³)min |

Electrode |

1.68-1.74 |

1.70-1.74 |

1.64-1.68 |

1.53-1.56 |

|

|

Nipple |

1.78-1.82 |

1.80-1.84 |

1.75-1.80 |

1.70-1.74 |

||

|

CTE (100-600℃)max |

Electrode |

1.1-1.4 |

1.1-1.4 |

1.6-1.9 |

2.2-2.6 |

|

|

Nipple |

0.9-1.2 |

0.9-1.2 |

1.1-1.4 |

2.0-2.5 |

||

|

Ash (%)max |

|

0.3 |

0.5 |

|||

|

|

||||||

price

Graphite Electrode 4 TPI Nipples Range and Nipples Size (4 buckles):

|

Nominal diameter(mm) |

Nipple type |

Nipple socket average diameter(mm) |

Nipple max diameter(mm) |

Nipple length(mm) |

Nipple socket depth(mm) |

Buckle length(mm) |

|

D4 |

D1 |

L1 |

L2 |

L3 |

||

|

800 |

432T4L |

428.64 |

431.80 |

635.00 |

323.50 |

319.50 |

|

750 |

406T4L |

403.24 |

406.40 |

609.60 |

310.80 |

306.80 |

|

750 |

406T4N |

403.24 |

406.40 |

584.20 |

298.10 |

294.10 |

|

700 |

374T4L |

371.49 |

374.65 |

558.80 |

285.40 |

281.10 |

|

700 |

374T4N |

371.49 |

374.65 |

457.20 |

234.60 |

230.60 |

|

650 |

355T4L |

352.44 |

355.60 |

558.80 |

285.40 |

281.40 |

|

650 |

355T4N |

352.44 |

355.60 |

457.20 |

234.60 |

230.60 |

|

600 |

317T4L |

314.34 |

317.50 |

457.20 |

234.60 |

230.60 |

|

600 |

317T4N |

314.34 |

317.50 |

355.60 |

183.80 |

179.80 |

|

550 |

298T4L |

295.29 |

298.45 |

457.20 |

234.60 |

230.60 |

|

550 |

298T4N |

295.29 |

298.45 |

355.60 |

183.80 |

179.80 |

|

500 |

269T4L |

266.72 |

269.88 |

457.20 |

234.60 |

230.60 |

|

500 |

269T4N |

266.72 |

269.88 |

355.60 |

183.80 |

179.80 |

|

450 |

241T4L |

238.14 |

241.30 |

355.60 |

183.80 |

179.80 |

|

450 |

241T4N |

238.14 |

241.30 |

304.80 |

158.40 |

154.40 |

|

400 |

222T4L |

219.09 |

222.25 |

355.60 |

183.80 |

179.80 |

|

400 |

222T4N |

219.09 |

222.25 |

304.80 |

158.40 |

154.40 |

|

350 |

203T4L |

200 04 |

203.20 |

304.80 |

158.40 |

154.40 |

|

350 |

203T4N |

200.04 |

203.20 |

254.00 |

133.00 |

129.00 |

|

300 |

177T4N |

174.64 |

177.80 |

215.90 |

114.00 |

110.00 |

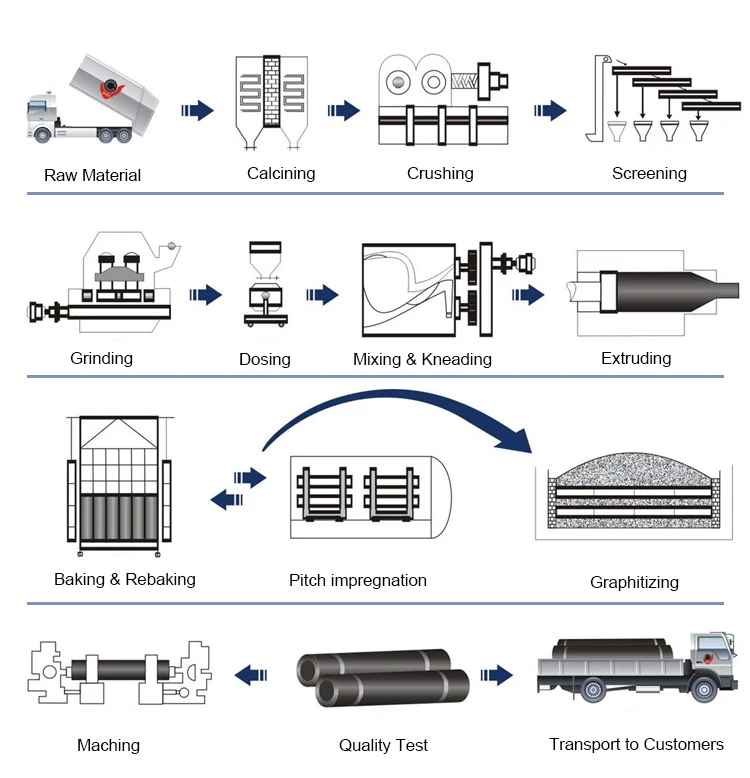

Full-line production Process of Graphite Electrodes RP HP UHP:

Work Diagram of Graphite Electrodes RP HP UHP in EAF:

UHP HP SHP RP Graphite Electrode factory price Best Sales from China

About CarboGraphite Industrial PTE.LTD

Founded in 1992, is a comprehensive carbon electrodes and related products manufacturer & exporter from China, products covering Graphite Electrode OEM, electrode paste, Refractory, Flake Graphite, Petroleum Coke, and related products. Maintaining the high quality of both our products and services is vital to the long-term success of our company. We cooperate closely with distributors and terminal customers in the steel, steel refining and non ferrous smelting industries worldwide. (P.S. We can export to Iran)

• Annual output: 50,000 metric tons, mass stock

• Strict quality control system, ISO9001 certified

• High purity needle coke

• Short lead time and on-time delivery guaranteed

• Your one-stop supplier, both stable product quality and rich experiences of after-sales service.

fangda graphite electrode

Technical Support

In CarboGraphite Industrial PTE.LTD, beyond the standard procedure of selling graphite electrodes, we have a group of experts and trained engineers focusing on delivering an entire service since receiving customer orders. We are familiar with all types EAF, Ladle, and Foundry applications. Rongxing Carbon guarantees all graphite electrodes meet the industry standard and will exactly meet customers' expections.

Annual Production Capacity

Graphite Electrodes: 50,000 MT

electrode paste: 200,000 MT

Calcined Coke: 250,000 MT

Refractories: 20000 MT

Stable Cooperation with Our Customers:

Packing &Shipping

sean@smeltingmateria

RP450 Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called “mini-mills”. They are also used in the refining of steel as well as in the non ferrous industries, where smelting processes are in use.

cindy@smeltingmateri

RP400 Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called “mini-mills”. They are also used in the refining of steel as well as in the non ferrous industries, where smelting processes are in use.

cindy@smeltingmateri

RP300 Graphite electrodes are used for the recycling of steel in the electric arc furnace industry, so called “mini-mills”. They are also used in the refining of steel as well as in the non ferrous industries, where smelting processes are in use.